Junior Euromat 2022 Organizing Committee wants to congratulate the winner of 2022 FEMS Master Thesis Award:

Nerea García de Albeniz, SOCIEMAT

Laser-assisted surface modification of zirconia-based materials to guide osteoblast response for dental applications.

FLUBETECH proudly offered a €300 prize to the winner.

The second place of 2022 FEMS Master Thesis went to Ivânia Trêpo, SPM – “Transparent and flexible EGoG electrode arrays of metallic nanostructures for neural recordings”.

The third place of 2022 FEMS Master Thesis went to Yann Bami-Chatenet, SF2M – “Elaboration of super-hydrophobic bio-inspired surfaces by hybrid 3D-manufacturing”.

We want to congratulate Noelia Solis (SCK CEN, Belgium) for winning the Best Poster Junior Euromat 2022 sponsored by FLUBETECH which offered a €300 prize.

Anna Hirle (TU Wien, Austria), the winner of the Best Poster in Vacuum Science sponsored by SOPORVAC. Huge congratulations to the winner of the €200 prize

The Portuguese Vacuum Society (SOPORVAC) was created in 1986 as a non-profit, technical and scientific organization. It is the Portuguese organism that represents IUVSTA (International Union for Vacuum Science, Technique and Applications). Its main goals are to promote and contribute to the study, discussion and dissemination of problems and techniques regarding vacuum related sciences and technologies, and inspiring ideas that favour its development.

PCO Secretariat:

Organideia – Organização Profissional de Congressos, Lda.

Av. da Guarda Inglesa, N.27, Santa Clara

3040-193 Coimbra, PORTUGAL

euromat22@organideia.pt

Chairs:

Sandra Carvalho

Co-chairs:

Albano Cavaleiro

Jorge Coelho

Title: Nanostructured Doped Nickel Oxide Thin Films Made By RF Sputtering As Hole Transfer Layers For Transparent Optoelectric Devices

In the last few years, the importance of transparent conducting oxide (TCO) thin films has increased enormously due to their potential applications in optoelectronic devices. Nevertheless, most TCOs are n-type semiconductors and only a few TCOs are p-type semiconductors. As a result, a scientific focus towards the development of new p-type TCOs is required. Nickel oxide (NiO) is one promising intrinsic p-type TCO that exhibits several attractive features like wide energy band gap, excellent chemical stability, and non-toxicity [1,2]. Thanks to its chemical stability and non-toxicity, NiO has found numerous applications in photo-bio-catalysis, sensing, microbatteries, and transparent optoelectronics like smart windows, ultraviolet (UV) photodetectors, and photovoltaics (PVs). In the case of PVs, NiO has been employed in conventional PVs and ultra-violet UV-PVs, additionally to perovskite PVs, in which it is used as a hole transport layer [3-6]. Due to the technological importance of NiO material, plenty of attempts have been made to change its properties depending on the application. Some dopants which have been used are: Al, Li, Cu, Nb, N for single doping or Li-Al, Li-Mg, and Cu-N for double doping. In the case where low-temperature depositions are performed, it is generally agreed that different dopants can result in different structural distortions which in turn have significant effects on the electronic structure, defect levels and, consequently, on the properties of the material [7].

The purpose of this master thesis was the fabrication of undoped NiO as well as doped NiO with dopants nitrogen (N), niobium (Nb), and co-doping (Nb-N) for modifying its properties. All films were made by RF sputtering technique on fused silica and silicon substrates at room temperature at 5 mTorr. Scanning Electron Microscopy (SEM) and Atomic Force Microscopy (AFM) were used for the morphological characterization of films. X-Ray Diffraction (XRD) was used for structural characterization, while Energy Dispersive X-Ray (EDX) and X-Ray Photoelectron Spectroscopy (XPS) for chemical characterization. Moreover, optical (UV-VIS) and electrical (I-V, Seebeck & Hall Effect) characterization were made. After the characterization of films, the optimum ones, just after fabrication or after thermal treatment at 300oC in N2, were chosen for fabrication of heterodiodes. The heterojunction diodes consisted of NiO as p-type semiconductor and TiO2 as n-type semiconductor. These diodes were characterized in the dark and under UV illumination.

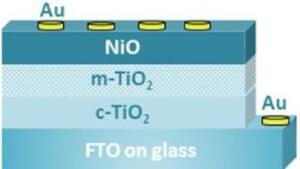

For the fabrication of p-NiO/n-TiO2 heterojunction diode (Fig.1), the n-TiO2 was fabricated by spin coating in a chemistry lab. The n-type TiO2 thin films consisted of two layers, namely a mesoporous TiO2 layer (m-TiO2) on top of a compact TiO2 layer (c-TiO2). Both of them were made by spin-coating on FTO/glass substrate. The structure m-TiO2/c-TiO2/FTO/glass was used as a substrate on which the undoped, doped or double doped NiO (NiO, NiO:N, NiO:Nb, NiO:Nb-N) were deposited in plasma. These films were chosen because they had optimum structural properties such as less lattice strain and optical properties such as higher optical transmittance.

Electrical measurements of diodes were made in dark before and after thermal treatment at 300oC. For analysis of electrical measurements, two different methods were used (I-V method & Cheung method). Finally, a UV laser at 325 nm was used and illuminated diodes from their backside. These measurements were made after thermal treatment of diodes at 300oC. From these diodes, only two gave UV photo-response. These devices consisted of Nb-doped NiO (NiO:Nb) and double-doped NiO (NiO:Nb-N) as p-type semiconductors. The diode, which has as p-type semiconductor the double doped NiO (NiO:Nb-N), had better output performance (Voc = 0.5V and Isc = 0.2 mA/cm2).

Figure 1: Schematic form of heterojunction diode.

Title: Transparent and flexible ECoG electrode arrays of metallic nanostructures for neural recordings

Unraveling the functioning of the brain has been one of the greatest challenges of the scientific community. Brain activity generates electrical signals that we can detect using an electrode made of a conducting material. The main purpose of this project was to fabricate transparent electrocorticography (ECoG) Microelectrode Arrays (MEAs). ECoG is an electrophysiological monitoring tool that uses MEAs placed in the brain surface to detect electrical signals generated from neural activity. A full understanding of how neurons – the building blocks of the brain – coordinate their activity to elegantly produce behavior in animals will require devices capable of sensing neural signals across multiple brain regions, ideally with the extra ability to simultaneously distinguish different types of neurons, as well as their exact location, which can be attained through optical imaging. Functional calcium imaging is a microscopy technique where the activity of genetically-identified neurons can be optically detected using fluorescent calcium-sensitive dyes or proteins into the cell membranes of neurons. However, these calcium signals are relatively slow and cannot give precise information about the timing of neural activity relative to animal behavior. In this way, the ECoG MEAs are able to combine the spatial resolution provided by functional calcium imaging, with the sub-millisecond temporal resolution of extracellular electrophysiology, offered by these ECoG electrodes [1]. Moreover, this device can cover a wide area of the brain surface, without penetrating the brain, measuring the dynamics of many neuron populations, thus providing a view of large-scale neural activity. For these reasons, the motivation for this work came from the need to innovate, produce and test transparent ECoG MEAs.

Primarily, it was desired that the device was flexible, so it could adapt to the curvilinear surface of the brain; being Parylene-C a common choice for these applications [2]. In addition, the electrodes needed to be transparent in order to be used alongside functional calcium imaging, but they also needed to be as conductive as possible. In such manner, there was an interplay to be considered between the resistivity of the chosen electrode material and its transmittance. Nowadays, in the field of transparent and flexible electronics, new materials and structures are being studied. There have been promising attempts to build transparent microelectrode arrays using Indium-Tin Oxide (ITO) [3] and graphene [4]. However, they were not widely adopted by neuroscientists. While graphene presents remarkable properties, its fabrication by reproducible and large-scale methods is still very challenging. Regarding ITO, due to indium scarcity and brittleness, a number of alternatives are currently under active research. Thus, Patterned Metal Grids (PMGs) are currently considered one of the best candidates due to their high electrical conductivity, optical transparency, mechanical robustness, and cost competitiveness [5]. Moreover, it is possible to optimize PMGs and MEAs dimensions down to the sub-micron scale by using state-of-the-art techniques such as Direct Laser Writing. Lastly, considering that the PMG material must be biocompatible, stable under physiological conditions, highly conductive, and somewhat flexible, gold appeared to be a suitable option.

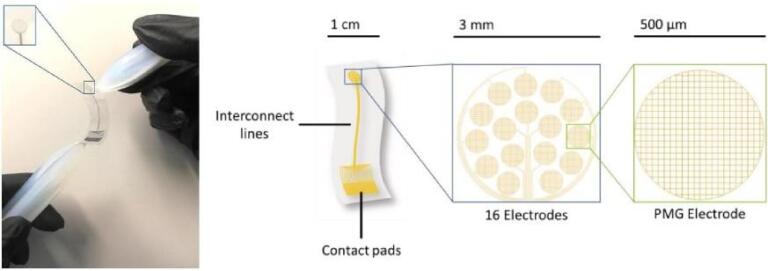

In this manner, transparent and flexible microelectrode arrays made of patterned metal grids were

produced using microfabrication techniques, namely maskless photolithography through direct laser writing, reactive ion etching, and electron beam evaporation of gold. Afterwards, the device was characterized in saline solution and also tested in mice cerebellum. Optimized patterned metal grids with 1 μm of linewidth and 22 μm of spacing showed an individual sheet resistance of 6 Ω/sq, and a transmittance of 80% at 550 nm. As for the device itself, the microelectrode array was composed by 16 electrodes with 500 μm of diameter distributed over a 1.5 mm radius circle. Additionally, an improved mechanical stability, through Parylene-C flexible substrate pretreatment, and an impedance of 13 kΩ at 1 kHz were attained. In vivo tests also showed the microelectrode array efficiency for its primary goal: recording brain activity.

Therefore, this project aimed to study and optimize, and then embed, gold PMGs in the electrodes so

they could be highly efficient, transparent, and conductive, providing both spatial and temporal resolution, with the ultimate goal of improving neural data acquisition.

Figure 1 – Overview of the transparent and flexible ECoG device

Title: Elaboration of super-hydrophobic bio-inspired surfaces by hybrid 3D-manufacturing

Superhydrophobic behaviour is a key in multiple industrial applications and is nowadays often based on polluting fluorine chemistry [1]. As environmental issues are put into light, an alternative is rapidly needed. Nature faces the same technological constraints as ours and develops green and sober solutions. For instance, in order to protect against bacteriological biofilms, leaves from numerous plant species exhibit superhydrophobic behaviours that rely on the combination of multiscale texturing and green chemistry [2,3]. Thanks to a biomimetic approach [4], we have the opportunity to understand the link between morphology and wettability in order to conceive alternative solutions.

By characterising surface morphology and wetting properties of multiple hydrophobic or superhydrophobic plant species, we have been able to suggest several hypotheses regarding the link between morphology and wettability. Micrometric morphology could have a decisive influence on hysteresis, precisely because of the impact of the contact line density on the triple line pinning, while nanometric morphology would rather control the static wetting angle. Nevertheless, identifying relevant morphological parameters for micrometric patterns in relation with wettability remains difficult, as wetting also critically depends on nanometric morphology and chemistry.

Another industrial challenge lies in understanding how to control a surface’s spreading anisotropy. In nature, many plant species rely on morphological anisotropy to control the direction of the water flow. Attempting to understand the link between spreading anisotropy and morphological anisotropy, we have developed numerical methods which enable us to assume that an isotropic texturing at a small scale can critically control spreading isotropy, screening an anisotropic texturing at a larger scale.

In order to confirm or to infirm those hypotheses, new experimental perspectives have been imagined: thanks to PDMS replicas, thanks to controlling the generation of epicuticular wax crystals, and eventually thanks to the use of X-ray microtomography, we are to better understand the proper contributions of micrometric morphology, nanometric morphology and chemistry to wettability. Furthermore, new fabrication techniques based on laser-matter interaction open up new opportunities for the fabrication of complex surfaces. Hybrid laser fabrication, which is the combination of additive and subtractive fabrication, will permit us to conceive complex multi-scaled metal surfaces, and to enable more performing superhydrophobic industrial materials.

Title: Laser-assisted surface modification of zirconia-based materials to guide osteoblast

response for dental applications

The surface topography of dental implants is a key parameter to achieve a strong and direct integration with the surrounding bone, however, the optimal topography that maximizes the osseointegration still remains unclear. Considering that, laser surface micro-patterning of dental-grade zirconia (3Y-TZP) was explored with the objective of providing a topography able to guide bone-cell response. A nanosecond laser was employed to fabricate micro-groove patterns on the surface of 3Y-TZP discs, yielding three different topographies according to the groove periodicity (30, 50 and 100µm). The resulting topography and surface damage of the three patterns was characterized by confocal laser scanning microscopy (CLSM) and scanning electron microscopy (SEM) techniques. Accelerated degradation tests were performed in water steam in autoclave (134ºC, 2bars, 10h), followed by X-Ray Diffraction (XRD) and Raman spectroscopy characterization to assess the hydrothermal degradation resistance of the modified topographies and compare it to control surfaces. Moreover, a cellular study was conducted to evaluate the behaviour of human mesenchymal stem cells (MSCs) on the patterned samples in terms of adhesion and cell morphology, to observe the relationship between the periodicities of the grooves and the response of the cells.

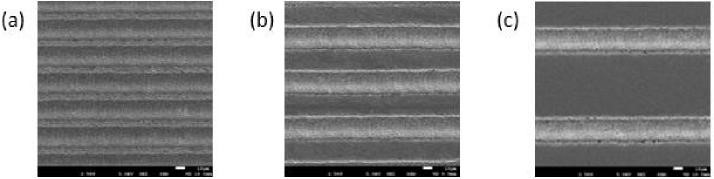

The laser modification allowed the patterning of groove structures of different periodicities: 30 (Figure 1.a), 50 (Figure 1.b), and 100 µm (Figure 1.c), denoted as L30, L50 and L100, respectively. The three surfaces consisted on well-defined and reproducible grooves, in which two spot could be differentiated: the laser valley (light grey), and the non-treated zone (dark grey) that became smaller as the periodicity decreased. Moreover, the profiles analysis of those topographies revealed that the three patterns consistented on a sequency of peak and valley structures. The total height of the grooves was about about 1.7µm, in the three cases. Also, the profiles of the patterns evidenced the formation of a very pronounced pileup in the sides on the grooves,which is attributed to the rapid local heating and flowing of the melted material that occurs when working in the nanosecond regime.

Figure 1. SEM micrographs of the grooved patterns created on zirconia. Groove periodicity: (a)30 (b)50 and (c) 100.

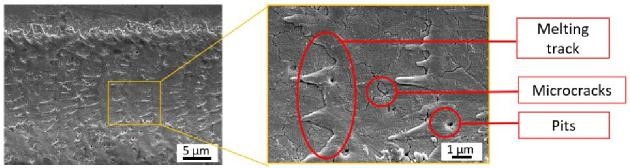

The effect of the photothermal mechanism was also evidenced by the melting tracks that appeared along the laser tracks, which are shown in the SEM magnifications of figure 2. Additionally, other surface damage such a microcracks and pits were observed in the laser structured surfaces.

Figure 2. SEM micrograph showing the surface damage appeared on the laser tracks.

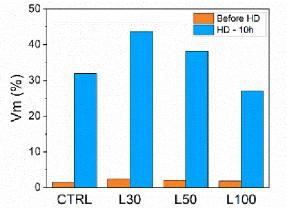

Figure 3 shows the monoclinic volume (Vm) calculated from the XRD analysis. The m-phase content was negligible in the non-degraded samples (orange bars) since it was lower that 2% in all cases (the control and the patterns), indicating that the laser processing seems not induce the martensitic transformation. However, after 10 hours of degradation in steam water, the t-→m- phase transformation was triggered in the four specimens (blue bars). The Vm increase calculated was 30.50% in the polished zirconia (CTRL), 41.31% in L30, 36.07% in L50, and 25.20% in the L100 sample. Therefore, these results indicated that long-term stability of 3Y-TZP was slightly decreased after the laser treated on the L30 and L50 samples when compared to the control.

Figure 3. XRD analysis of the samples before and after 10h of degradation.

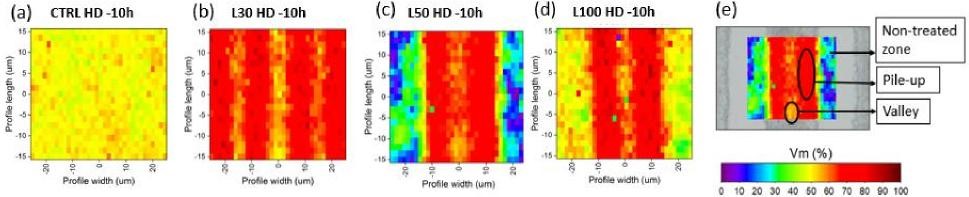

Raman spectroscopy analysis was in accordance with the XRD results showing the presence of Vm on all the samples after 10h of degradation (Figure 4a-d). Moreover, the Raman mapping evidenced a non-homogeneous m-phase distribution along the surface of the aged and patterned 3Y-TZP samples (Figure 4.b-d), but not in the control (Figure 4.a). In particular, the three spots indicated in Figure 4.e were differentiated: the non-modified part, the laser valley zone, and the pileup, which is the most transformed zone in the three laser structured topographies.

Figure 4. Raman spectroscopy of the samples before after 10 hours in water steam (a) CTRL, (b) L30, (c) L50, and (d) L100.

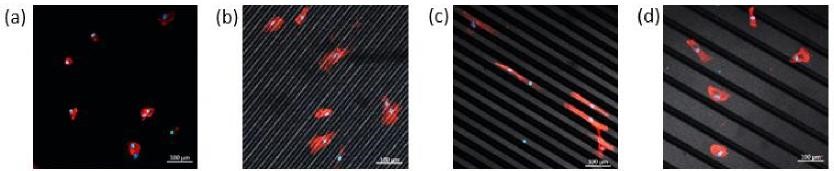

Finally, a cell adhesion assay was performed in order to investigate the influence of the microgrooved patterns on hMSC adhesion and morphology. The fluorescence LCSM images revealed that the three micropatterns enabled MSC attachment (Figure 5.b-d) and increased cell area compared to polished zirconia (Figure 5.a). Moreover, cell morphology and alignment were influenced by the periodicity of the patterns. Among all the microtopographies, only the 50 µm periodic pattern (Figure 5.c), which better mimics the size of the cells, significantly favoured cell elongation and alignment along the grooves.

Figure 5. Fluorescence LCSM images fron the hMSCs adhesion test after 6h of incubation: (a) CTRL, (b) L30, (c) L50, and (d) L100. In the images, the acting filament is stained in red and the nuclei in blue.

Therefore, in this study it was demonstrated that nanosecond laser patterning is a successful approach to produce microgroove patterns on zirconia material in a relatively fast and unexpensive way. The resulting topographies were composed by a sequency of valley-pileup structures, that only decreased slightly the hydrothermal degradation resistance of zirconia. But most importantly, it the cell adhesion study it was demonstrated that the 50 µm periodic pattern was able to tune bone cell response by favouring hMSC migration.

DDS, PhD, AFHEA

Auxiliary Professor (Lecturer) of Dental Materials and Operative Dentistry, Instituto Universitário Egas Moniz (IUEM), Almada, Portugal

Honorary Research Fellow – Biomaterials and Tissue Engineering, Faculty of Medical Sciences, UCL Eastman Dental Institute, London, United Kingdom

Antonio obtained his DDS degree at Instituto Universitário Egas Moniz, Portugal in 2017. He continued his research activity at IUEM, where he works as a researcher in the field of dental materials science for the Centro de Investigação Interdisciplinar Egas Moniz (CiiEM) unit since 2017. Antonio also completed research training in Hong Kong briefly, in dental materials science, before starting his PhD in Biomaterials & Tissue Engineering at UCL Eastman Dental Institute in early 2018. Antonio’s PhD was in polymer chemistry, with a specific focus in vibrational spectroscopy for the characterisation of dental materials. Since 2015, Antonio has published in various national and international peer-reviewed scientific journals, has delivered many poster presentations and talks in national and international conferences related to materials science. Antonio has had chairman roles and invited talks in major conferences such as the FDI World Dental Congress and IADR/CED-IADR Meetings. Antonio serves as an Ambassador for Portugal in the Young CED-IADR Board. He has experience in supervising/co-supervising MSc Theses and has had teaching roles both at IUEM (Portugal) and at UCL (UK), in dental research, operative dentistry and materials science. Antonio’s career is research-based with expertise in materials science, teaching and consultancy.

Title: ATR-FTIR/Micro-Raman Spectroscopy are powerful techniques to disclose chemistry and polymerization of novel smart self-adhesive composites

António HS Delgado1,2*, Anne M Young2

*1Centro de Investigação Interdisciplinar Egas Moniz (CiiEM), IUEM, Almada, Portugal

2Division of Biomaterials and Tissue Engineering, UCL Eastman Dental Institute, London, United Kingdom

Understanding physico-chemical properties of dental composites is pivotal to predict their behaviour in the oral environment. However, it is often required to employ several different techniques to characterize materials. To overcome this, vibrational spectroscopy can be used to simultaneously assess chemical composition, filler type/distribution, filler/polymer ratios, and free-radical addition polymerization kinetics of composites. Three commercial self-adhesive materials (ActivaTM Kids, AK; Constic, CC and VertiseTM Flow, VF) and one experimental (SMART_1) were tested. SMART_1 was prepared by combining urethane dimethacrylate, poly(propylene glycol) dimethacrylate and adhesive monomer 4-META, with a hybrid glass filler phase containing remineralising particles of monocalcium phosphate and antibacterial poly-l-lysine (powder/liquid ratio=3:1). An ATR-FTIR was used to determine real-time polymerisation kinetics of 2×10 mm composite discs (37ºC). A semi-quantitative model was constructed based on the Beer-Lambert Law to analyze composition. Polymerized discs were polished and assessed using micro-Raman, by mapping a 40×40 mm area to characterize filler chemistry/dispersion. ANOVA with Tukey’s HSD were employed to compare means (a=0.05). Modelling was consistent with CC/VF having 35% Bis-GMA and AK 45% UDMA. Degree of conversion was largely material-dependent (ANOVA, p<0.001), with Constic showing the highest (82±2%), while ACTIVA the lowest (67±2%). Rates showed a similar trend. Shrinkage was greater in Constic (5.8±0.1 vol%) and VF (5.3±0.1) when compared to SMART_1 (4.6±0.1; p<0.05). ACTIVA showed the largest particles (>12 μm), with a high filler/polymer ratio, while CC/VF had similar microstructural features. It can be concluded that ATR-FTIR/Raman techniques are especially valuable to characterize novel dental polymer formulations and compare them to commercial competitors.

Junior Euromat 2022 is pleased to announce Prof. Rodrigo Martins as Moderator of our ERC Grant Day event.

Rodrigo Martins currently is:

Full Professor at FCT-NOVA |President of European Academy of Sciences EurASc

President of the International Union of Materials Research Societies

Director of Centre of Excellence in Microelectronics, Optoelectronics and Processes of UNINOVA

Member of the Scientific Council of the European Research Council

Topics

Rodrigo Martins | How materials answer to the demands of society in critical areas: energy; water; food and IoT, among others?

Telma Carvalho | What is the impact of the new panel in Physical Sciences and Engineering domain on attraction of talents in the area of Materials?

Tomas Polcar | How a suitable strategy for education can be used for the attraction of talents in the area of Materials?

Francesco Matteucci | How to educate young talents on science frontiers raised by brightest minds keeping entrepreneurial mindset in materials?